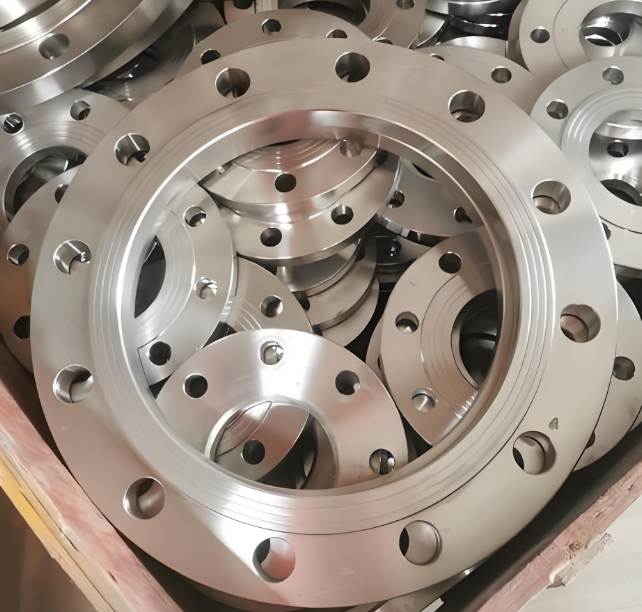

Stainless Steel Socket-weld Flange

Stainless Steel Socket-weld Flange

- For connections of pipes of relatively small diemension (0.5"-4")

- Suitable for low temperature and pressure application

Stainless Steel Socket-Weld Flange

Durable Precision for Small-Bore Piping Systems

Product Overview

The Stainless Steel Socket-Weld Flange is a high-performance fitting designed for seamless integration into small-diameter piping systems requiring leak-proof connections in demanding environments. Its socket-weld design ensures robust mechanical strength and corrosion resistance, making it ideal for critical applications in industries such as oil and gas, chemical processing, and pharmaceuticals

Key Features

Material Superiority: Constructed from ASTM A182 F304/F316 stainless steel, offering exceptional resistance to corrosion, high temperatures, and aggressive media.

Compact Design: Optimized for DN15-DN100 (½"-4") pipelines, with a compact structure that simplifies installation in confined spaces

Leak-Resistant Joint: Features a recessed inner diameter (ID) to align with the pipe, creating a smooth flow path and minimizing turbulence

Pressure Range: Suitable for ASME Class 150 to Class 3000 systems, ensuring compatibility with low-to-medium pressure requirements

Interchangeability: Compatible with standard gaskets, bolts, and lap joint flanges for flexible system configurations

Design & Construction

Socket-Weld Connection: The pipe is inserted into the flange’s socket and welded externally, forming a strong, permanent joint resistant to vibration and thermal cycling

Raised Face (RF) or Ring-Type Joint (RTJ): Available with RF surfaces for standard sealing or RTJ grooves for high-pressure applications

Expansion Gap: A 1.6mm-3.2mm gap between the pipe end and flange shoulder accommodates thermal expansion, preventing stress fractures

Applications

Oil & Gas: Instrumentation lines, pump discharge lines, and valve manifolds

Chemical Plants: Handling corrosive fluids, acids, and high-purity media

Pharmaceuticals: Hygienic systems requiring crevice-free surfaces and CIP/SIP compliance

Technical Specifications

| Material Grades | SS304, SS316, SS316L, Duplex 2205 |

| Size Range | ½" to 4" (DN15 to DN100) |

| Pressure Classes | ASME 150#, 300#, 600#, 900#, 1500#, 2500#, 3000# |

| Standards | ASME B16.5, B16.11, MSS SP-83, ISO 15649, DIN 2576 |

| Surface Finish | Electro-polished, sandblasted, or natural mill finish |

Installation Guidelines

Pipe Preparation: Ensure pipe ends are square-cut and deburred for full insertion into the socket

Tack Welding: Align the flange and pipe, then secure with tack welds before final circumferential welding

Gap Maintenance: Maintain the specified expansion gap to prevent joint stress26.

Certifications & Compliance

PED 2014/68/EU (Category I-IV)

ISO 9001:2015 quality management

NACE MR0175 for sour service environments